Electrode Paste Hanging: Causes and Solutions

In addition to customers' concerns about high electrode paste consumption, the issue of electrode paste clumping—often referred to as electrode paste hanging—is another critical focus. Electrode paste hanging occurs when paste blocks become lodged in the electrode shell and fail to descend, creating significant voids within the paste column. During measurement, if the paste column height remains unchanged for an extended period (e.g., over 8 hours), and yellow smoke subsequently emerges from the electrode shell, hanging is likely occurring. If unaddressed, this can lead to electrode hard breaks, soft breaks, or even explosions inside the electrode shell.

Main Causes of Electrode Paste Hanging

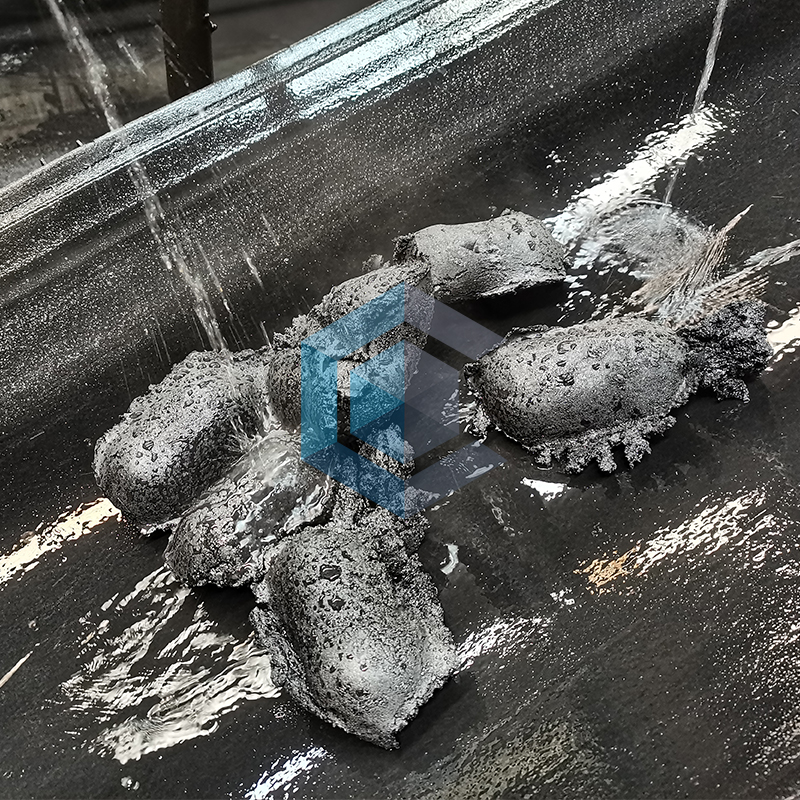

Oversized Paste Blocks: Large paste blocks may become stuck between the ribs of the electrode shell, preventing descent.

Excessive Paste Column Height: High paste columns reduce upper-segment temperatures, hindering melting and sintering.

Low Winter Temperatures: Intermittent operation of heating elements in cold weather results in insufficient sintering.

Foreign Object Ingress: Large contaminants entering the electrode shell can block the paste flow path.

Solutions

Control Paste Column Height: Maintain the paste column within the process-specified range (e.g., 4.5–5.0 meters) to avoid excessive height or shortages.

Optimize Particle Size: Ensure paste粒度 (particle size) complies with standards (e.g., ≤100 mm) to prevent bridging or segregation.

Ensure Continuous Heating: In winter, sustain consistent heater operation to avoid intermittent sintering.

Strengthen Protective Measures: Install covers atop electrode shells to prevent debris ingress.

Timely Intervention: If the paste column shows no movement for 8 hours, use a rope-weighted object to dislodge the blockage or cut open the shell for清理 (cleaning).

The more we understand electrode paste, the clearer it becomes that paste-related issues often cannot be attributed solely to paste quality. In fact, furnace operation practices are equally crucial. Rongxin Electrode Paste is committed to collaborating with customers to continuously study and improve electrode paste performance in practical applications, fostering mutual growth.

Phone:+86 19937179450

Phone:+86 19937179450

Whatsapp:+86 19937179450

Whatsapp:+86 19937179450

Email:

Email: Add:Zhengdong New District,Zhengzhou City,China.

Add:Zhengdong New District,Zhengzhou City,China.