Solving Electrode Paste Challenges: A Guide to Formulation, Types, and Sustainable Sourcing

In the high-stakes world of submerged arc furnaces (SAFs) and electric arc furnaces (EAFs), consistent and reliable operation is paramount. At the heart of this operation lies a critical component: Electrode Paste. This self-baking consumable is the lifeline of your furnace, directly impacting productivity, cost-efficiency, and overall operational stability.

However, many operators face persistent issues like Electrode paste breaking, Electrode paste shedding, and unexpectedly Electrode paste high consumption. These problems lead to costly downtime, unsafe working conditions, and spiraling operational expenses. Understanding the root causes—often linked to Electrode paste formulation and quality—is the first step toward a solution.

The Root of the Problem: Why Electrode Paste Fails

Common failure modes are frequently traced back to the core ingredients and manufacturing process.

Electrode Paste Caking: This occurs when the paste softens and agglomerates during storage or transport, making it difficult to handle and feed smoothly into the electrode column. It's often a sign of inconsistent binder quality or improper temperature control.

Breaking & Shedding: When an electrode lacks structural integrity, it can fracture or shed material into the furnace. This is a severe hazard that disrupts the smelting process and can damage the furnace lining. The primary culprit is usually an inferior Electrode paste formulation that fails to provide the necessary mechanical strength during the baking phase.

High Consumption: While consumption is inevitable, excessively high rates eat into your profitability. This can be caused by suboptimal raw materials (e.g., low-quality calcined coke or anthracite) that lead to rapid oxidation and erosion.

The Foundation of Quality: Electrode Paste Formulation and Raw Materials

A superior Electrode Paste is a precise blend of solid aggregates and a binder. The choice of aggregates defines its conductive and thermal properties.

Calcined Coke Electrode Paste: Formulations based on high-purity calcined coke offer excellent electrical conductivity and low ash content. This is the preferred choice for high-power applications like ferroalloy and calcium carbide production, where efficiency and purity are critical.

Anthracite Electrode Paste: For standard applications, Anthracite Electrode Paste provides a cost-effective and robust solution. Anthracite coal offers good thermal stability and resistance to oxidation, making it suitable for silicon metal and pig iron production.

The art of the perfect Electrode paste formulation lies in the precise ratio and mixing of these aggregates with coal tar or petroleum pitch binders. A reputable Electrode Paste Plant employs rigorous quality control to ensure every batch delivers consistent performance, preventing the common issues of caking and breaking.

Choosing the Right Shape for Optimal Performance

The physical shape of the Electrode Paste is designed for efficient handling and a consistent baking profile. The three most common types are:

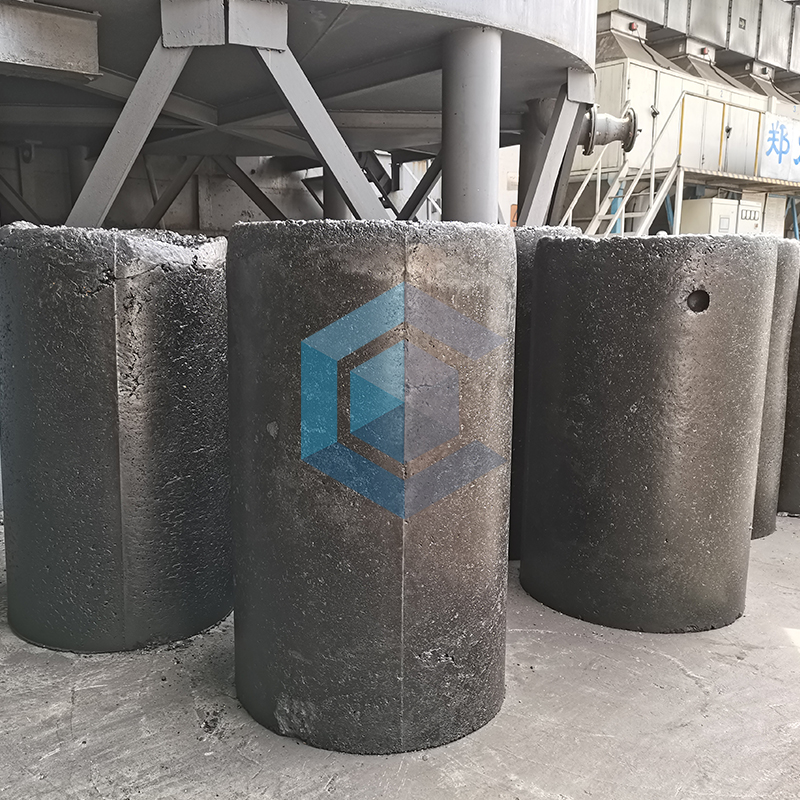

Cylindrical Electrode Paste: The standard shape, offering a good balance of strength and ease of use.

Trapezoidal Electrode Paste: This shape provides a tighter seal within the contact clamps, reducing air ingress and oxidation. It's often preferred for its improved structural stability in the electrode column.

Egg-shaped Electrode Paste: Designed for seamless feeding and optimal surface-to-volume ratio, the egg shape ensures a smooth descent and uniform baking, minimizing the risk of paste sticking and creating a more stable electrode.

Your Strategic Partner for Reliable Electrode Paste Export

Navigating the complexities of Electrode Paste Export requires a supplier with global logistics expertise and an unwavering commitment to quality. Fluctuations in the market and unreliable supply chains can jeopardize your entire production schedule.

When you partner with a trusted global supplier, you secure more than just a product; you gain a strategic advantage. We specialize in the Electrode Paste Export of high-performance pastes, including both Calcined Coke Electrode Paste and Anthracite Electrode Paste, in all standard shapes (Cylindrical, Trapezoidal, and Egg-shaped Electrode Paste).

We understand that Electrode paste high consumption and unexpected failures are not an option. Our dedicated Electrode Paste Plant leverages advanced R&D to create formulations that maximize electrode life and furnace stability, directly addressing the pain points of breaking and shedding.

Ready to Optimize Your Furnace Operation?

Stop letting electrode paste problems control your bottom line. Contact us today to discuss your specific requirements. Let us provide you with a reliable, high-quality Electrode Paste solution that enhances efficiency, reduces downtime, and drives your success.

Phone:+86 19937179450

Phone:+86 19937179450

Whatsapp:+86 19937179450

Whatsapp:+86 19937179450

Email:

Email: Add:Zhengdong New District,Zhengzhou City,China.

Add:Zhengdong New District,Zhengzhou City,China.